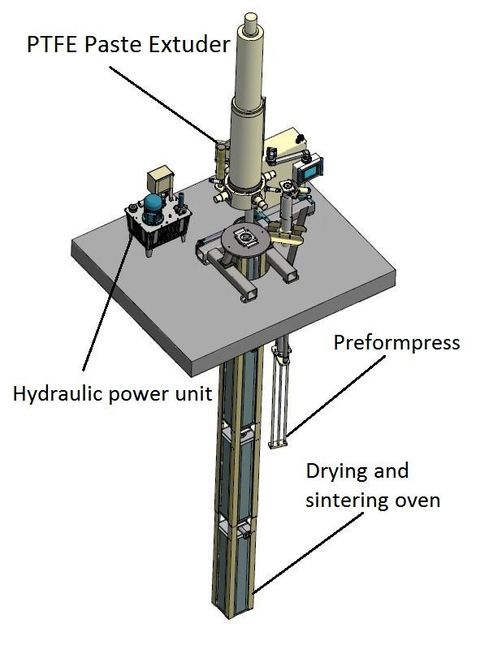

PTFE Paste Extrusion Line

for the Production of PTFE- tubes by PTFE- Paste Extruder

The process is done in batch quantities

The PTFE lubricant mixture firstly is pre-pressed to so-called pre-forms by unse of a preform press and then put into PTFE Paste extruder which works on the priciple of the ram extrusion. Then the pre-form is pressed through a conic noozle in cold or slightly pre-heated condition. The extrudate is separated from the still containing lubricant within the drying zone and then sintered.

PTFE extrusion process with a PTFE Extruder also known as PTFE Paste Extruder or only PTFE Extruder

Paste extrusion is applied the PTFE production of thin hoses, thick tubes (liners), wire insulation and unsintered tapes of PTFE. For the PTFE Paste extruder exclusively emulsion polymerization powder is used. The paste is a mixture of these spongy PTFE powder types with wetted organic fluids.

Complete PTFE Paste Extrusion Line consists of

- Mixer

- Preform press

- Paste Extruder

- Drying oven

- Sintering oven

- Winder

KEICHER offers a combination of

- Preformpress

- PTFE Paste Extruder

- Drying Oven

- Sintering Oven

- Handling between the Units

- Touchscreen Control of complete System

Drying oven

For better installation Keicher delivers the drying oven in sections the type of heating is infrared.

Range of temperature:

- 100°C - 250°C

- 210°F to 480°F

Preform Press

Keicher supply Preform presses in same sizes like paste extruder sizes.

That means:

- diameter size up to 300mm (12″)

- length up to 1200mm (48″).

Sintering oven

For better installation Keicher delivers dteh drying oven in sections the type of heating is infrared.

Range of temperature:

- 200°C - 500°C

- 400°F to 930°F

How to find us on YouTube