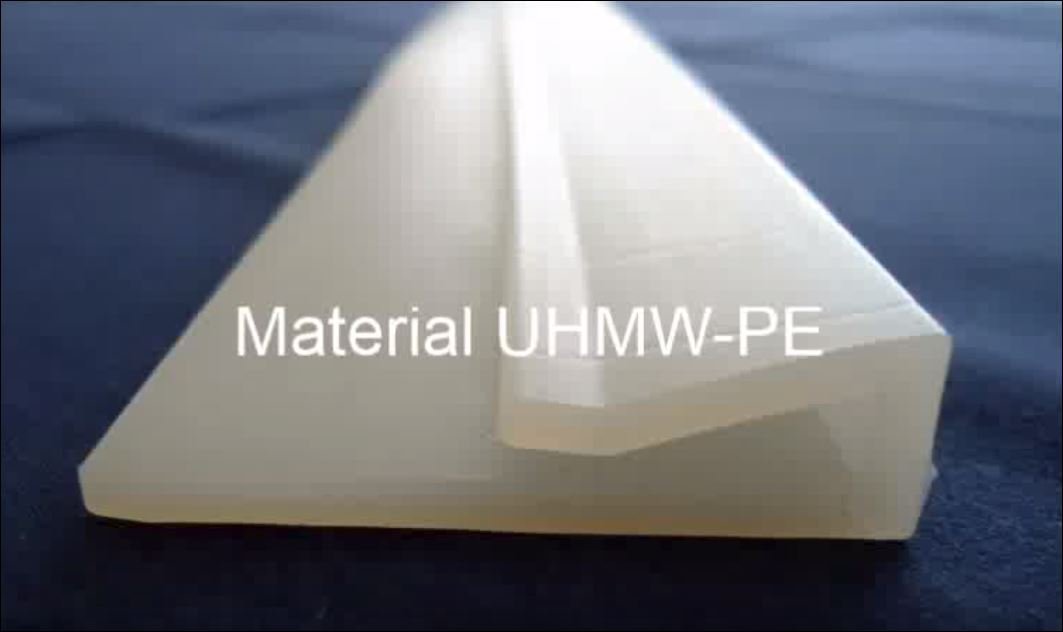

Horizontal RAM Extruder

World Class Solution in UHMW-PE Technology

Our UHMW-PE RAM ExtruderThe brand name is GUR

Ram extrusion is a pressing process enabling the continuous manufacture of sections. Especially of UHMW-PE (ultra hight molecular weight polyethylene). The basic material is UHMW-PE powder is fed into a cylindrial extrusion pipe, compressed by means of a ram and, at the same time, transported through the pipe, which is heated up to sintering termperature. The individual dosing charges sinter together into a continous Extrudate.

Advantages of Keicher RAM-Extruders or PTFE-Extruders

- Horizontal desing to reduce space of UHMW-PW RAM-Extruder

- Short set-up time through easy and quick die change

- Canstant high quality of the products through permanent electrical measurement and precise temperature regulation

- Uniform and exact dosing through electronix dosing system

- User-friendly and maintenace-free

- Possibility of stepwise extension to a complete automatic manufacturing system through modular construction

- Operation through touchscreen and recording of the exhausion parameters

- Safe operation date

- Automatic adjustin of extruder and heatings acoording to preexisting recepts

Aviable Toolings

- Single rods

- Single profiles

How to find us on YouTube